Basic Knowledge for a Civil Engineer

Concrete Grades

M7.5= 1 : 4 : 8

M10 = 1 : 3 : 6

M15 = 1 : 2 : 4

M20 = 1 : 1.5 : 3

Note: M20 & above grade based on Design Mix

M10 = 1 : 3 : 6

M15 = 1 : 2 : 4

M20 = 1 : 1.5 : 3

Note: M20 & above grade based on Design Mix

Example:-M15 concrete mix has a mix proportion of 1:2:4 of cement, fine aggregate, and coarse aggregate respectively.

M15 – M represents Mix and 15 N/mm2 is the characteristic compressive strength of concrete cube at 28 days.

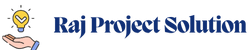

Reinforcement

- Minimum bars for square column is 4 No’s and 6 No’s for circular column.

- Main bars in the slabs shall not be less than 8 mm (HYSD) or 10 mm (Plain bars) and the distributors not less than 8 mm and not more than 1/8 of slab thickness.

- Lapping is not allowed for the bars having diameters more than 36 mm.

Slump IS 456

- Lightly reinforced 25 – 75 mm.

- Heavily reinforced 75 – 100 mm.

- Trench fill (insitu & Tremie) 100 – 150 mm (For Tremie no need of vibrator).

Test on Fresh concrete

- Slump Test- Workability

- Compacting Factor Test

- Vee-Bee Test

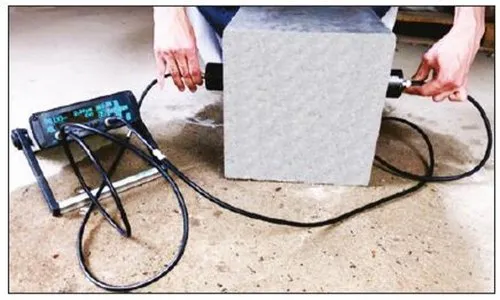

Test on Hardened Concrete

Rebound Hammer Test

Ultrasonic Pulse Velocity Test

Curing Days Required

- Super Sulphate cement : 7 days.

- Ordinary Portland cement OPC : 10 days.

- Minerals and Admixture added cement : 14 days

more than 200mm for filling above structure and 300 mm for no structure.